The adhesive coating and laminating process

Coating

We adhesive coat, laminate together and reinforce various types of paper, vinyl and metal materials in order to obtain products with unique, features which are impossible to find elsewhere.

The adhesives

The adhesives used are acrylic, solvent/emulsion and hot melt

Production Flow

La produzione di materiale adesivo si compone sostanzialmente di due parti: spalmatura; taglio e confezionamento

The adhesive coating and

laminating process

We adhesive coat, laminate together and reinforce various types of paper, vinyl and metal materials in order to obtain products with unique, features which are impossible to find elsewhere.

Il Coating

We adhesive coat, laminate together and reinforce various types of paper, vinyl and metal materials in order to obtain products with unique, features which are impossible to find elsewhere.

Some of the available materials:

- Single-sided and double-sided adhesive aluminium

- Self-adhesive and double-sided adhesive PVC Film Production

- Self-adhesive Polyester Film Production

- Self-adhesive Polypropylene Film Production

- Self-adhesive Polyethylene Film Production

- Self-adhesive Polyethylene Foam Production

- Self-adhesive paper production

- Self-adhesive satin, nonwowen and Tyvec Production

- Heat-sealing Kraftliner ribbon production

PVC and other vinyl and polyester products, either silk screen printed or printed using other graphic types, are used to create labels and prints that should resist, when applied to exterior surfaces subject to any adverse weather conditions.

According to their characteristics, they are resistant to low and high temperatures, UV rays and anything that can accelerate deterioration.

Some are used when resistance is also required transparency, such as for window transparencies.

Another use is to provide strengthening and shock resistance. Their uses are virtually endless.

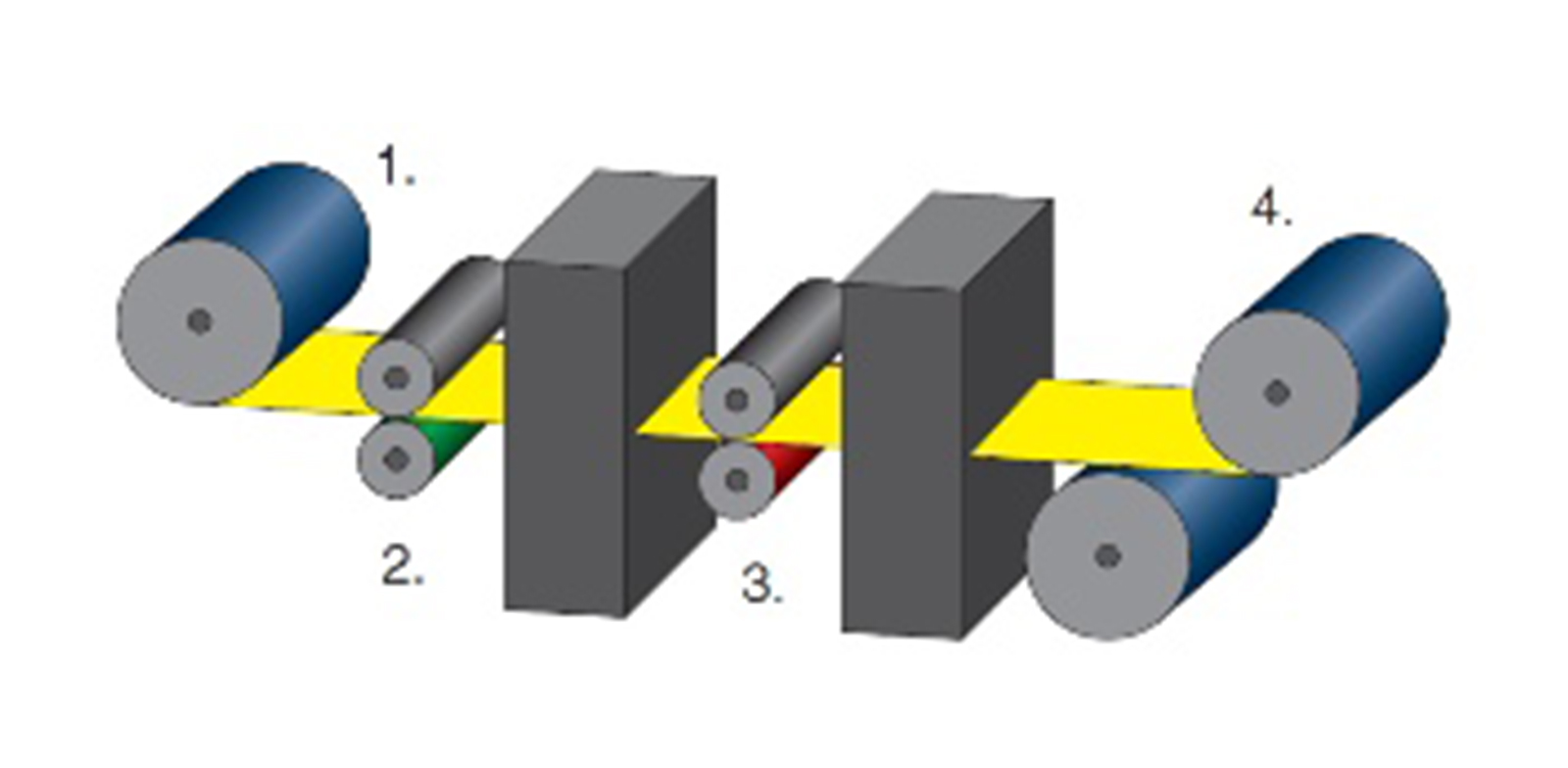

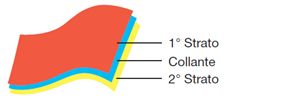

The components in the adhesive coating and laminating process

1. The liner – the carrier material which is removed during application of the adhesive product.

2. The release – the layer necessary in order to remove the adhesive front from the liner.

3. The adhesive – there are different types of adhesive with physical characteristics that can ensure the.

4. The front – various types, selected from hundreds and hundreds of paper/vinyl/metal materials, carefully chosen in order to ensure the level of performance required from the customised application.

5. Other materials to be laminated – in this process, there may be one or more materials to be laminated to the front (duplex or triplex).

THE ADHESIVES

The adhesives used are acrylic, solvent/emulsion and hot melt

Hot-melt adhesive

This is an adhesive obtained from the fusion of synthetic resins and thermoplastic rubbers and has good adhesive properties up to 50-60 °C. It is solvent-free and so is environmentally-friendly. It has high levels of adhesive properties, is not affected by moisture but has limited resistance to temperature and ageing and poor resistance to solvents.

Natural rubber-based solvent adhesive

Adhesive composed of natural rubber and resins dissolved in solvent (hexane). In the coating phase, the solvent is made to evaporate in order to obtain the “consistent” adhesive. Good tack, average adhesive properties, not affected by heat. Moderate resistance to solvents. Easy to remove and reasonable adhesion even on difficult surfaces.

Water-based acrylic adhesive

Adhesive composed of acrylic resins in water dispersion. In the coating phase, the water is made to evaporate. Good heat resistance, average adhesive properties, good resistance to solvents and ageing. Poor resistance to moisture.

Solvent-based acrylic adhesive

Adhesive composed of acrylic resins in a solvent solution. In the coating phase, the solvent is made to evaporate. Excellent resistance to heat, good adhesive properties, excellent resistance to ageing and moisture. Suitable for outdoor applications.

The silicones available for products which come in sheets are::

- Single sided poly coated | 73 gr

- Single sided poly coated in the following weights | 75, 135, 160 gr

The silicones available for products which come in reels are:

- Glassine | 62, 80 e 90 gr

- Polyester | 75gr

- All the single coated and single sided poly coated silicones

PRODUCTION FLOW

The production of adhesive material consists essentially of two parts::

- Coating

- Cutting and packaging

Coating

This is the phase in which the adhesive is applied to the medium. Pasqui has the following coating ranges:

- Hot-melt coating

- Rubber-based solvent coating

- Acrylic coating

- Special tape coating

Reel cutting

The cutting processes normally used are:

Blade cutting – This is the most common cutting system, in which the reel of semifinished product is unwound and the adhesive-coated film passes through the cutting area where the blades are positioned on a bladeholder and spaced out with a fixed pitch.

Pressure cutting – The tape obtained through this type of cutting, also known as “crush cutting”, has the characteristic of being easy to tear by hand, as the edge of the rolls after the cut is slightly serrated.

Scissor cutting – Type of cut used for processing semi-finished products with a large consistency (in terms of thickness and resistance) when classic blade cutting cannot be used.

Sheet cutting – The self-adhesive material is cut into sheets in sizes ranging from 100 x 100 cm to 50 x 100 cm. Subsequently, the format of the product can be further reduced using a paper cutter.