RFid Labels production and printing

RFID SOLUTIONS FOR TRACKING AND TRACING

Oriented towards product innovation, we have been interested in the study of new applications helped by evolutionary tracking and tracing techniques. We design smart labels which can perform complex functions. Thanks to joint-ventures with qualified developers of integration technology solutions and renowned microprocessors manufactures, we are able to propose ourselves by these synergies, as a partner for setting up complete projects based on RFID technology. The aim of our R&D group is to link basic with applied research and industrial implementation to offer tailored made solutions with added value.

What is RFid?

RFID stands for Radio Frequency Identification. This term indicates those technologies that allow objects and people to be recognised at a distance using radio waves.

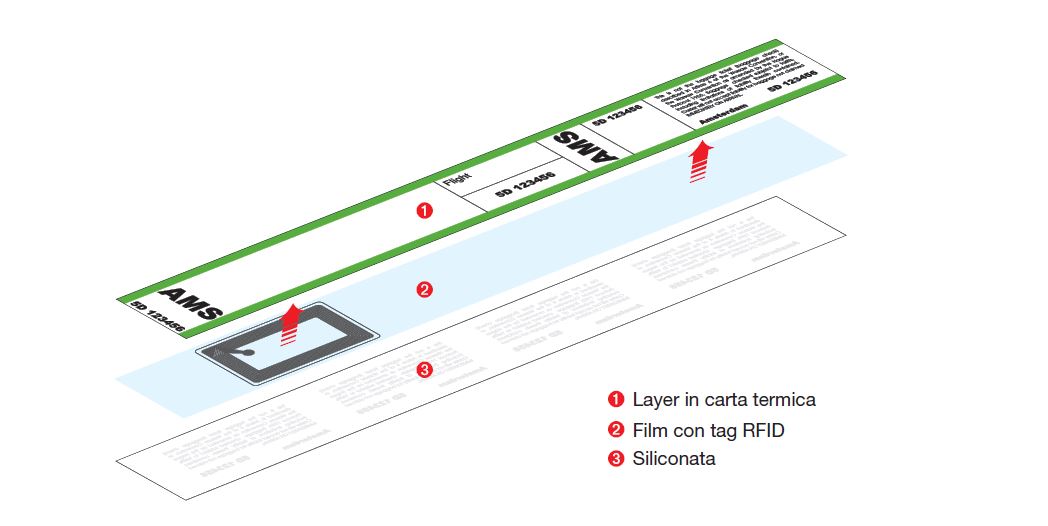

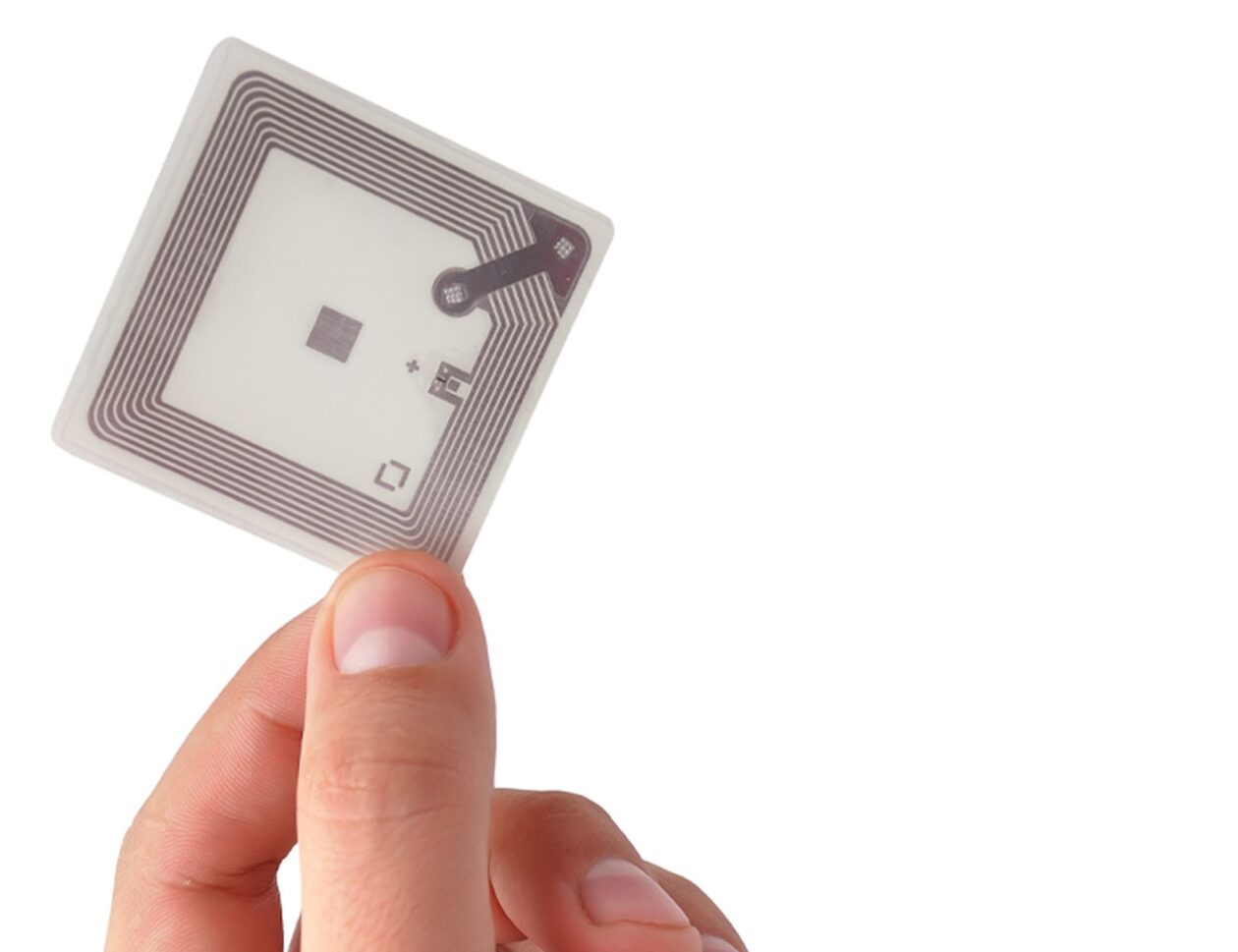

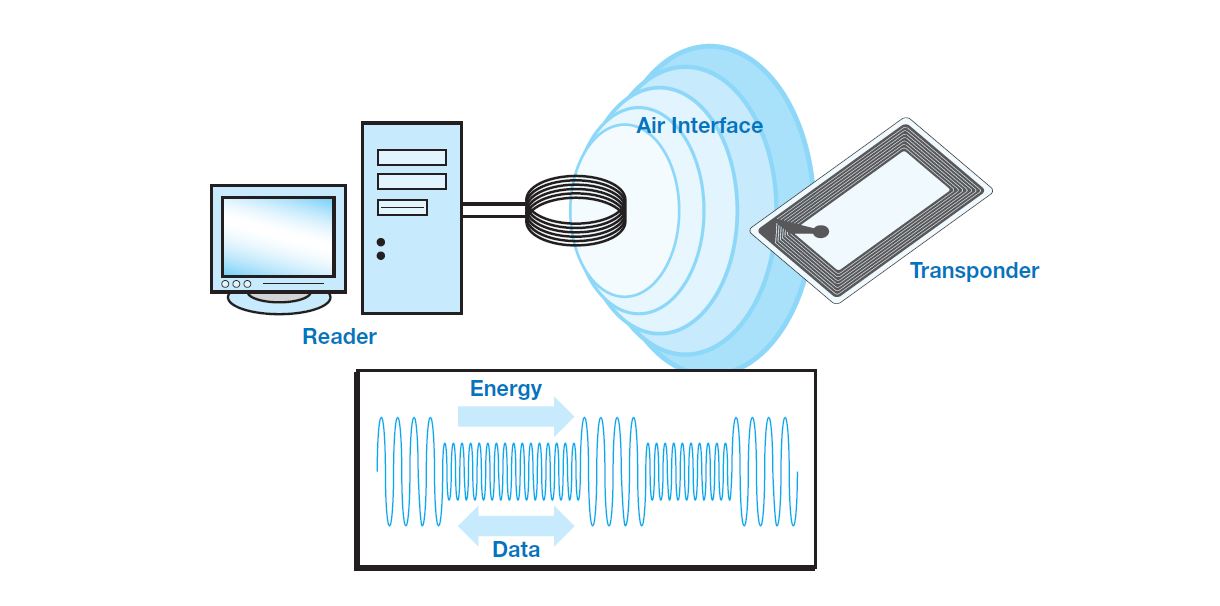

A radio frequency identification system consists of two main components: a transponder or tag and a reader. The tag is the label that is affixed to the object. This contains all the information relating to it and which identifies it uniquely. The data, stored in a microchip, can be read by an antenna that receives and transmits radio signals to and from the RFID reader. The microchip and the antenna together form the RFID tag and are placed on a medium.

The reader is the device, fixed or portable, for reading the RFID tags, and can convert the tag’s radio waves into a digital signal that can be transferred onto a computer. In order for the tags and the reader to communicate, they must be tuned to the same frequency..

What are the frequencies used by RFID?

RFID systems use different frequencies, which can be classified as:

– low frequencies (LF, between 125 and 134 kHz)

– high frequencies (HF, about 15 MHz)

– ultra high frequencies (UHF, 860 to 960 MHz)

– microwaves (greater than 2.45 GHz)

The various frequency bands have different characteristics and are suitable for different applications. In general, as the frequency increases, so do the reading distance and the amount of information that can be transferred in the period of time, while the resistance to operating conditions and costs decrease. The low-frequency tags use very little power and are able to cross non-metallic materials and liquids, but the signal for reading does not exceed 30-40 cm.

The high-frequency tags work better with metal objects and are able to cover a distance of about one metre. The ultra high frequencies provide wider reading ranges and the ability to transfer data faster, but do not cross the materials easily. Solutions with 2.45 GHz tags are used for electronic toll collection, freight and the like.

How are the tags powered?

RFID tags come in three types: passive, semi-active or active.

Passive tags have no internal power source and take the power required to activate the circuits from radio waves sent by the reader, which interrogates them and induces a current in the antenna. According to ISO rules, LF and HF tags can only be passive, while tags at UHF and microwave frequencies can also be semi-active or active.

A semiactive tag has a power source. This does not power the radio circuits, but additional functions such as temperature or motion sensors.

Active tags are powered by batteries that offer a greater range to the radio signal and an increased reading distance. Active tags cost more than passive tags and are best suited to tracking the transport of valuable goods over long distances.

Can the information on the tags be overwritten or deleted?

There are “read only”, “write once & read many” or WORM and “read & write” types of label. In the first two types, the RFID tag represents a technological evolution of the bar code, as the information stored on the microchip cannot be modified once it has been written. Read & Write mode, however, is the most flexible. The tag can be used as a dynamic memory, because information on the chip can be updated at any time, for example along the steps of the production chain. These are generally slightly more expensive than read only tags.

Compared with bar codes and other identification technologies, radio frequency technology offers many benefits: reading does not require direct contact and optical sight, so there is no need to direct it towards the scanner. The tags can be read simultaneously, can work in dirty, contaminated environments and can withstand very difficult conditions (environmental agents, thermal, chemical, mechanical stress). They can also operate immersed in a fluid, inside the object to be identified or inside a container. RFID tags are more expensive than bar codes, but the cost-effectiveness is generally beneficial. It would, though, be wrong to think that RFID technology will take over from bar codes. Much more likely, the two will coexist.

What is EPC Gen 2?

EPC Gen2 means EPC Generation 2. It is the second generation EPC protocol, designed to operate at international level. EPC Gen is at the center of attention because it seems likely that a convergence between the UHF Gen 2e standards and a revision of ISO 18000-6 will take place. All the stakeholders (industry, ISO, EPC Global) are keen for this to happen. The unification process could contribute to further acceleration in the adoption of RFID on a global scale.

Labels in the near future? RFID, the boom of “chipless” labels

A study conducted by the Research and Markets analysis firm shows that over the next ten years, chipless labels could become players in the RFID market. The “Printed and Chipless RFID Forecasts, Technologies & Players 2007-2017” report says that today, the market share of chipless labels is very low, only 0.4 percent. In the world, in fact, almost 2.5 billion tags were sold in 2006, of which 100 million were chipless. But the forecasts are for a veritable boom. So much so that, by 2016, their market share could reach 45 percent.

These labels do not contain an incorporated silicon microchip and operate by reflecting a portion of the radio waves, so that a receiving reader is able to read and identify the object. Their range is ten metres and they can store up to 256 bits of data. One of the advantages of chipless labels is their extreme flexibility: with no silicon inside them, in fact, they are resistant to greater stresses than the tags normally used.

And that’s not all. The absence of silicon also leads to lower costs: without chips, tags can cost a tenth of the price of conventional labels. That’s why, today, they are used by major brands such as AstraZeneca and Calvin Klein. And in the future, the number of applications will certainly increase. Also thanks to innovations that companies of the calibre of Philips, PolyIC, OrganicID and Motorola are working on, the plan being to build transparent polymer transistors (on which chipless labels are based) to print directly onto the product to be tagged.