Copper and Aluminum Production

Single-sided and double-sided adhesive aluminium production for the refrigeration industry

Single-sided adhesive aluminium is particularly suitable for joining aluminium-coated insulating panels and for coating air conditioning system pipes. Both single and double-sided aluminium are used for the distribution of the cold to operate refrigerators.

Mono & biadhesive aluminium tape

FRONT

Aluminium, temper 0 alloy 1050, thickness 30 ÷ 350 μm

ADHESIVE

Hotmelt or solvent based Acrylic, grammage 10 ÷ 60 g/m²

LINER

Single side poly coated paper, on request we can use different

siliconised papers

USES

The 150-350 μm aluminum is used for the production of domestic and industrial refrigerator where it finds natural application between the refrigerator container and the cooling coil. It allows excellent thermal efficiency and high cost reduction compared to traditional systems used. The lower thickness are generally used for joining insulation panels made of aluminum cladding and for covering pipelines in the air conditioning systems. Aluminium has excellent strength aging and acts as a barrier to moisture and steam.

Laminated aluminium

FRONT

Aluminum foil reinforced with polyester or polypropylene and surface treated with release to allow detachment from itself.

ADHESIVE

Solvent based acrylic

USES

The lamination with polyester or polypropylene gives greater strength. It ‘s used for sealing and improves heat dissipation.

Freezer tape

FRONT

Polyolefin copolymer film with surface treated with release to allow detachment from itself.

ADHESIVE

Rubber based Syntetic

USES

It’s used for the sealing and protection of the coils of refrigeration.

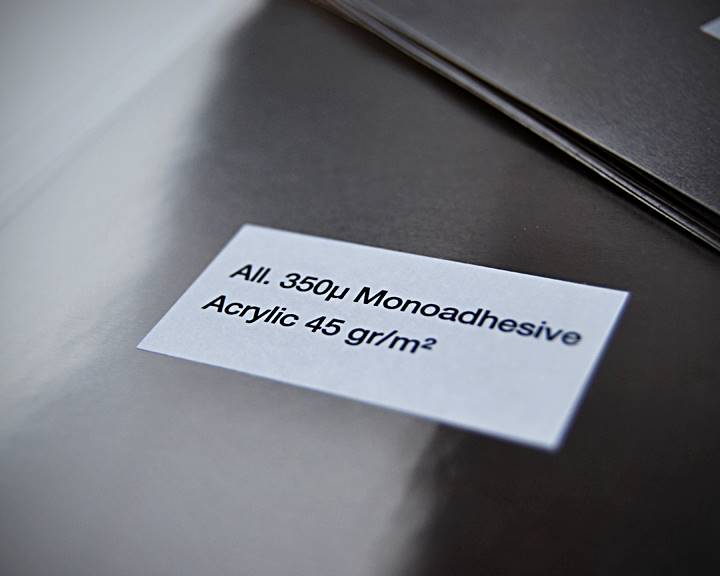

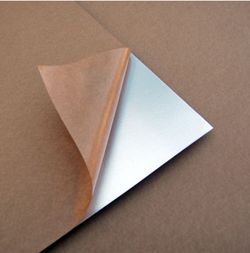

Monoadhesive aluminium sheet

FRONT

Aluminium, temper 0 alloy 1050, thickness 30 ÷ 350 μm

ADHESIVE

Hotmelt or solvent based Acrylic, grammage 10 ÷ 60 g/m²

LINER

Single side poly coated paper, on request we can use different siliconised papers.

USES

As the tape, it allows the improvement of thermal exchange and heat dissipation. The sheet is designed for manual applications.

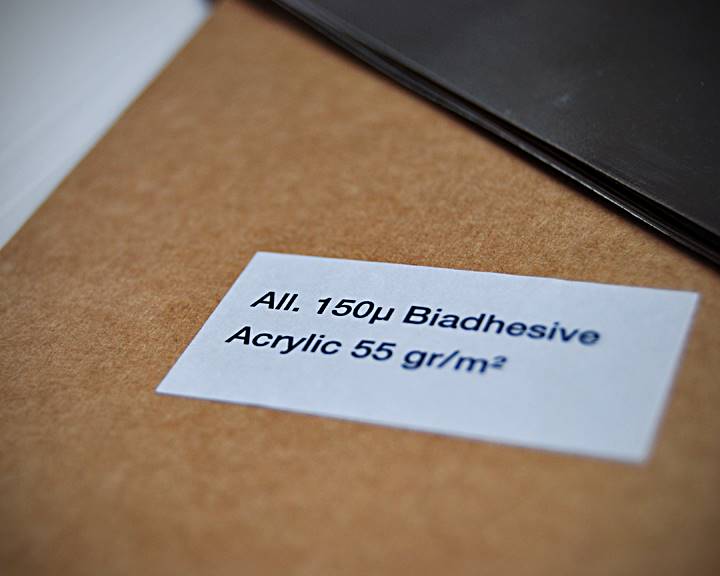

Biadhesive aluminium sheet

FRONT

Aluminium, temper 0 alloy 1050, thickness 30 ÷ 350 μm

ADHESIVE

Hotmelt or solvent based Acrylic, grammage 10 ÷ 60 g/m²

LINER

Single side poly coated paper, on request we can use different siliconised papers.

USES

As the tape, it allows the improvement of thermal exchange and heat dissipation. The sheet is designed for manual applications.

Mono & biadhesive aluminium die cutted sheet

FRONT

Aluminium, temper 0 alloy 1050, thickness 30 ÷ 350 μm

ADHESIVE

Hotmelt or solvent based Acrylic, grammage 10 ÷ 60 g/m²

LINER

Single side poly coated paper, on request we can use different siliconized papers

USES

It allows the improvement of thermal exchange and heat dissipation. The die cutting make it in the design required by the Customer.

Related links:

- Single-sided and double-sided adhesive aluminium

- Self-adhesive and double-sided adhesive PVC Film Production

- Self-adhesive Polyester Film Production

- Self-adhesive Polypropylene Film Production

- Self-adhesive Polyethylene Film Production

- Self-adhesive Polyethylene Foam Production

- Self-adhesive paper production

- Self-adhesive satin, nonwowen and Tyvec Production

- Heat-sealing Kraftliner ribbon production

Type

Structure

Adhesive

Size

Uses

Mono & Biadhesive Aluminium

Aluminium foil (30, 50, 80, 150 e 350 μm) with siliconised liner

Solvent based Acrylic (temperature until –45°C) or Hotmelt (temperature until –30°C)

Made into reel, width min 50mm and max 1000mm or made into sheet width max 1000mm die cutted too

Thermal exchange and heat dissipation

Laminated Aluminium

Aluminium foil (9 μm) with polyester film (23 μm)

Aluminium foil (30 μm) with polypropylene film (28 μm)

Solvent based Acrylic

Solvent based Acrylic

Made into reel, width min 25mm and max 50mm

Made into reel, width min 30mm and max 50mm

Sealing, thermal exchange and heat dissipation

Freezer Tape

LDPE-EVA Polyolefin copolymer film (total thickness 85 μm)

Rubber based Syntetic

Made into reel, width min 50mm and max 900mm

Fixing, sealing and protection of the coils